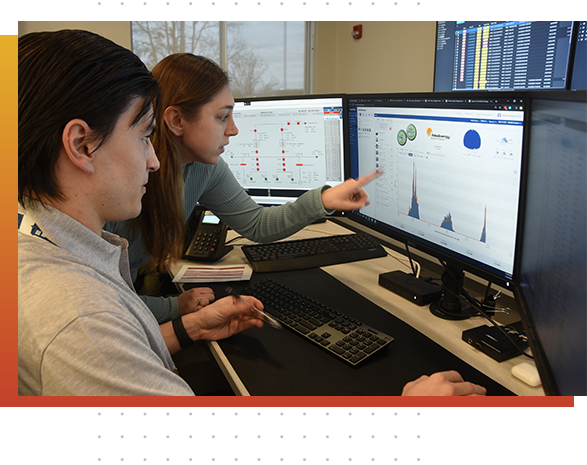

Monitoring System / Equipment

All PV systems are unique. We begin our partnership by establishing a connection with the system’s SCADA that allows for data to feed into our robust monitoring and analysis platform. Extensive data filtering occurs prior to feeding into the analysis platform, allowing for quick and accurate analysis. By using a standardized platform, a uniform response can be made irrespective of the SCADA design.

Accurate Projections

Accurate expected yield metrics are created as a function of irradiance, temperature and “As-Built” system parameters. Modeled system performance is compared to hourly performance, providing an immediate view into potential system health and model underperformance. Using this designed analysis, our team is able to differentiate between events that require immediate attention and those that signify the need for future site work, keeping your site up and running.

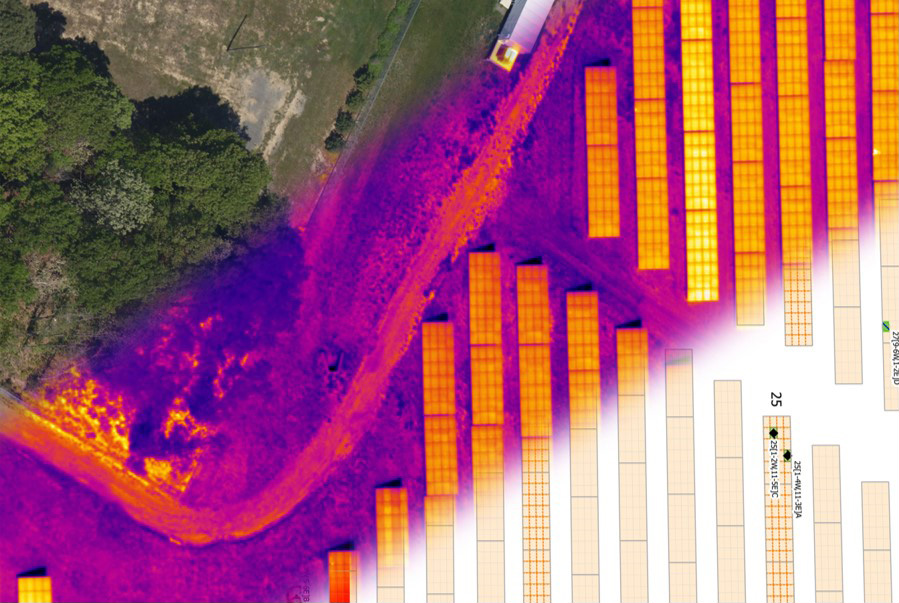

Plant Health

Through performance analysis, regular system health checks will occur through all levels of the plant. Data trending is used to identify issues such as disconnected DC fields, tracking angle errors, and transformer pressure control problems. When a plant is added into our platform, our automated alarm and analysis tools allow us to place a priority on system health.

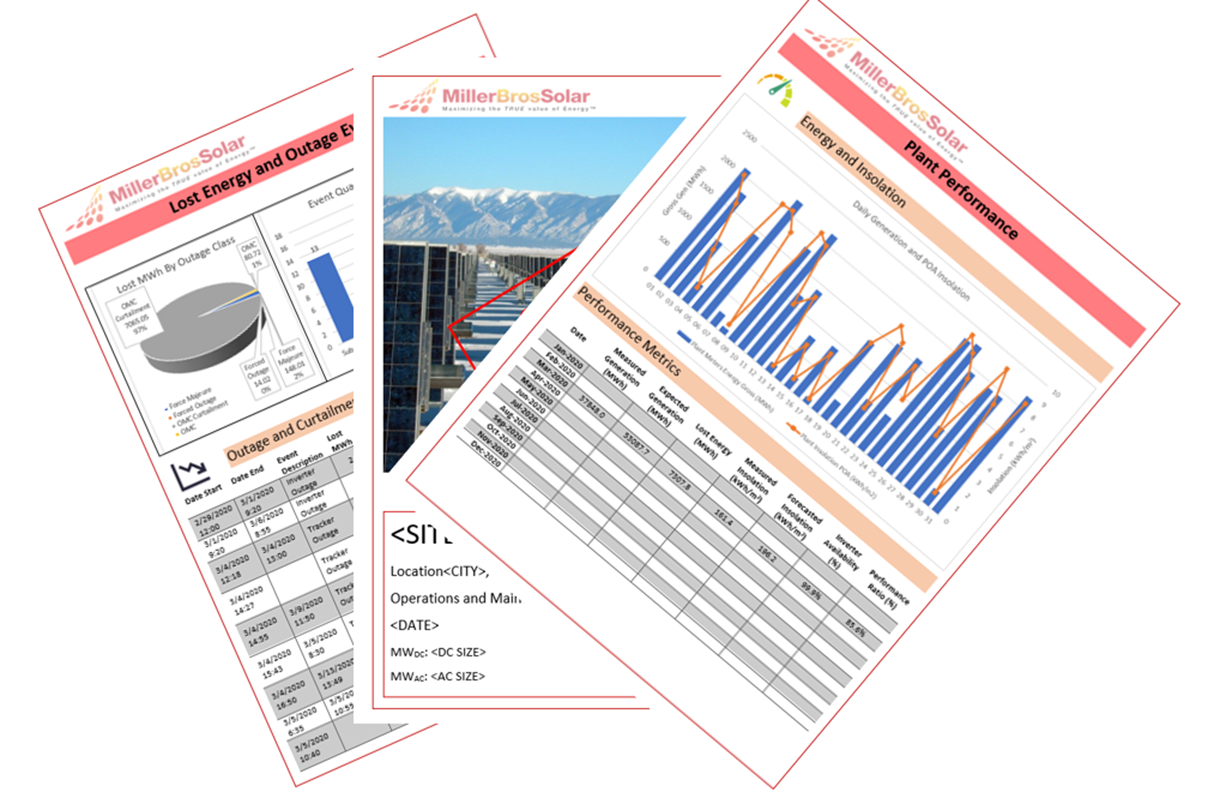

Performance Reporting

Analysis is only effective if reported clearly and concisely. By following strong data filtering methods and using an established analytics platform, a comprehensive and detailed report is generated that covers performance metrics, operational events, and maintenance activity.

We’ll only use your information for the following:

- To process your request for information.

- Register you to receive our newsletters.

- To contact you about our services and products.